| Availability: | |

|---|---|

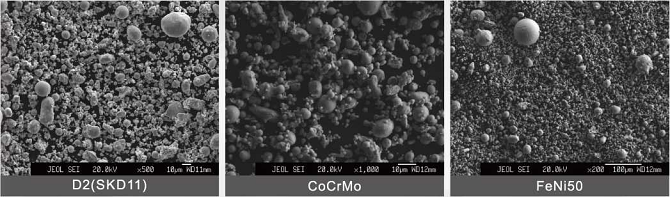

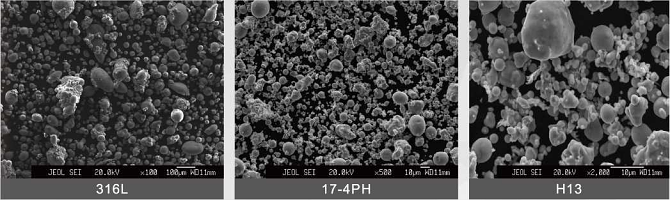

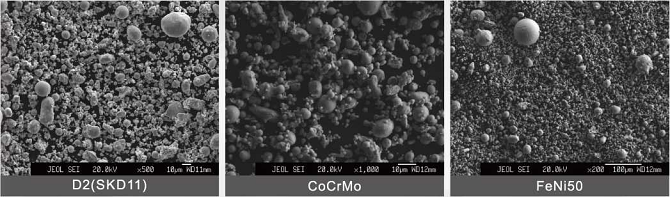

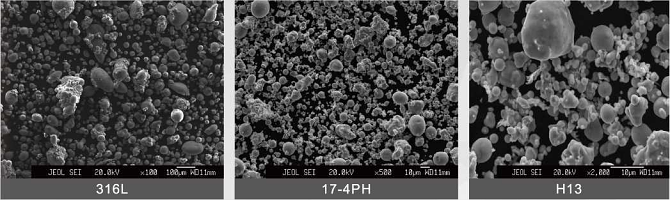

Product features:All kinds of stainless steel low alloy steel and tool steel alloy powders produced by vacuum atomization or water gas combined atomization can provide powders with different particle sizes from 3pm to 13pm, which can meet the requirements of different shrinkage ratio and different sintering density. The parts made of this kind of powder have the characteristics of low sintering temperature, high sintering density and good feeding fluidity.

We can also supply stainless steel powder and tool steel powder, other specifications are available upon any customer requirements.

Specifications

| Products | Process | D50 (m) | T.D(g/cm3) | O.C.(ppm gas) | O.C.(ppm water) | Specifications (mesh) |

| 316L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 317L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 310S | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 304L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 17-4PH | water and gas combined atomization /gas atomization | 5-10 | ≥4.6 | ≤600 | ≤3700 | -500/-800 |

| 440C | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤2000 | -500/-800 |

| 430L | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3500 | -500/-800 |

| 410L | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3200 | -500/-800 |

| 420 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| M2/MA | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| H13 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| D2(SKD11) | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| CoCrMo | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤500 | ≤3000 | -500/-800 |

| FeNi50 | water and gas combined atomization /gas atomization | 8-13 | ≥4.8 | ≤500 | ≤3000 | -325/-400 |

| FeSiAl | water and gas combined atomization /gas atomization | 8-13 | ≥4.5 | ≤500 | ≤3500 | -325/-400 |

| 4340 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 4365 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 4605 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 8620 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

Application

Product features:All kinds of stainless steel low alloy steel and tool steel alloy powders produced by vacuum atomization or water gas combined atomization can provide powders with different particle sizes from 3pm to 13pm, which can meet the requirements of different shrinkage ratio and different sintering density. The parts made of this kind of powder have the characteristics of low sintering temperature, high sintering density and good feeding fluidity.

We can also supply stainless steel powder and tool steel powder, other specifications are available upon any customer requirements.

Specifications

| Products | Process | D50 (m) | T.D(g/cm3) | O.C.(ppm gas) | O.C.(ppm water) | Specifications (mesh) |

| 316L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 317L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 310S | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 304L | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤600 | ≤3500 | -500/-800 |

| 17-4PH | water and gas combined atomization /gas atomization | 5-10 | ≥4.6 | ≤600 | ≤3700 | -500/-800 |

| 440C | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤2000 | -500/-800 |

| 430L | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3500 | -500/-800 |

| 410L | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3200 | -500/-800 |

| 420 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| M2/MA | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| H13 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| D2(SKD11) | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤3000 | -500/-800 |

| CoCrMo | water and gas combined atomization /gas atomization | 5-10 | ≥4.7 | ≤500 | ≤3000 | -500/-800 |

| FeNi50 | water and gas combined atomization /gas atomization | 8-13 | ≥4.8 | ≤500 | ≤3000 | -325/-400 |

| FeSiAl | water and gas combined atomization /gas atomization | 8-13 | ≥4.5 | ≤500 | ≤3500 | -325/-400 |

| 4340 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 4365 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 4605 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

| 8620 | water and gas combined atomization /gas atomization | 5-10 | ≥4.5 | ≤500 | ≤4000 | -500/-800 |

Application